7 Key Impacts a Better Throughput Gives Your Company

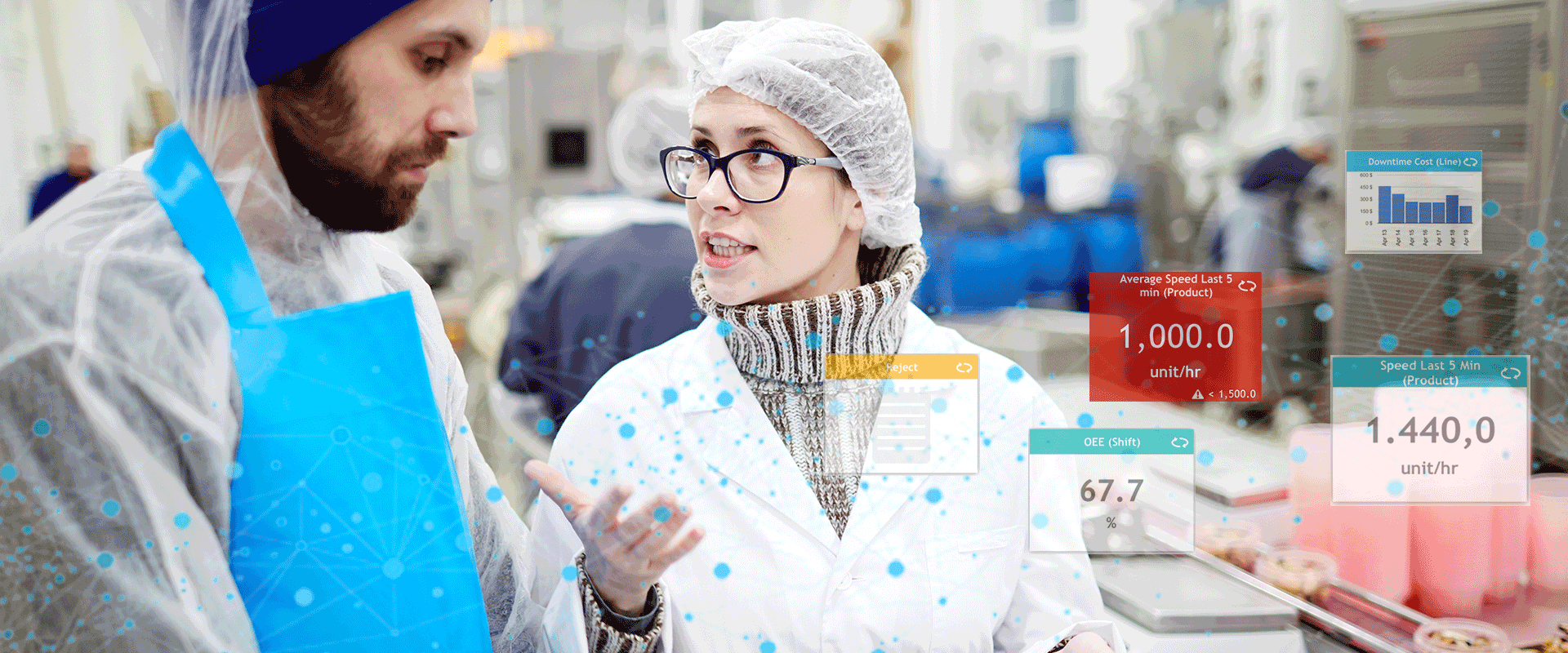

The most crucial metric for manufacturing is throughput. Production output refers to the quantity of goods that are manufactured or produced within a specific timeframe. Every machine within a production plant has its throughput rate, which ultimately contributes to the overall throughput of the entire plant. Tracking and improving this can be difficult, but it is possible with the right methods and technology.

-

Enhanced throughput has a significant impact on reducing downtime:

If your company has the demand, having more output can lead to increased sales and satisfied customers. By improving efficiency and minimizing downtime, you can increase the number of items available for shipping to customers, thereby ensuring that your products remain in stock on the shelves. This results in satisfied customers who purchase what you sell whenever they require it.

2. The improvement in throughput has a positive impact on profitability.

Increasing sales leads to a larger profit margin. Improving efficiency and increasing throughput enables prompt shipments that meet established quotas, resulting in profitability when goods are sold.

3. Improved throughput can provide a competitive advantage.

Maintaining a competitive advantage is crucial in today’s market. By ensuring timely deliveries, you can increase sales and secure your position in the market. Having a higher throughput than your competitors can provide you with a competitive advantage. Customers desire prompt deliveries and a wide range of choices. Find more info about throughput

4. The production efficiency can be positively impacted by an improvement in throughput.

Efficient production means that your equipment utilizes time more effectively, resulting in higher throughput. An efficient production process implies that you are operating at or close to maximum capacity. This implies that reduced time and cost are incurred on equipment downtime and restarts.

5. The improvement in throughput to achieve balanced manpower:

Reducing waste and balancing manpower are achieved by increasing throughput. When there is high throughput with few downtimes, employees will be able to be productive most of the time, which reduces labor waste.

6. The improvement in throughput has a positive impact on lowering facility costs.

Optimizing throughput implies that you are maximizing the efficiency of your equipment and utilizing your factory space to its fullest potential. Machines that are not in use may incur a capital cost, as well as additional expenses related to occupying space. These expenses may include rent or property taxes, as well as the cost of energy required to light, heat, or cool the space where the machines are located.

7. The improvement of throughput has a positive impact on reducing energy consumption.

Investing in technology that monitors production will offer you comprehensive data on the performance of your machinery. This information will offer valuable insights into the effectiveness and consumption of energy, aiding in the planning of strategies to reduce energy bills.

Conclusion:

Increased throughput improves energy efficiency. Real-time monitoring cuts down overproduction and downtime, saving energy. This technology assists operators while also reducing labor shortages.